corporate information

Our partners around the world already benefit from using our customized measurement and calibration system. The following projects describe the extraordinary use of our measuring systems

DSn Miniture

The measurement of the airspeed vector of a quadcopter using a multi-hole probe from a German manufacturer. The technical challenge here is to realize the pressure scanner with minimal weight and dimensions in order to minimize the influence on the flight behavior of the test object. In order to be able to use the system independently, the system is supplied with energy by two caps and the pressure data is recorded on the integrated memory and read out using RFID after the flight. The operating time of the scanner corresponds to the average flight time (approx. 8min) of a quadcopter weighing less than 250g. The data is recorded at 30 Hz, which provides a sufficient resolution of the flow vector.

Structural Health Monitoring of a wing

Hydrofoils apply high loads to their wings, fuselage, and masts. Additionally, they get structural stress through impacts with floating object or ground contact. Due to the necessity of light weight, most of the components are made from fiber structures. In contrast to most metals, a fiber structure is continuously weakened by changing loads, since the individual fibers tear with every load change, thereby permanently reducing the strength of the component. In order to be able to test the wear of the individual components non-destructively, the components were equipped with piezo actuators to detect fiber tears. The sensors and data collection have been adjusted accordingly to not affect the current and to be salt water resistant.

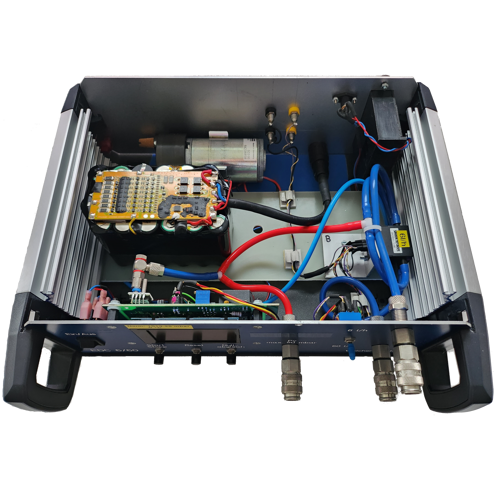

EDC extended

A small, but smart upgrade to the leak testing device. Due to customer demand we modified the pressurization components to increase the test pressure to 5bar gauge, while keeping the remote operation functionality of the device. The rise of the test pressure could be achieved with a new pump unit and an adapted pressure controller to damp the blade spikes of the pump. The energy supply has been switched from lead acid to a lithium ion battery, with a quick charge capable BMS. While the leak testing unit is still qualified for transportation in most airlines, due the small capacity of the battery, the test time is still comparable with the lead acid version.